Functionally reliable valve technology

Special valve technology solutions through to universally applicable basic components

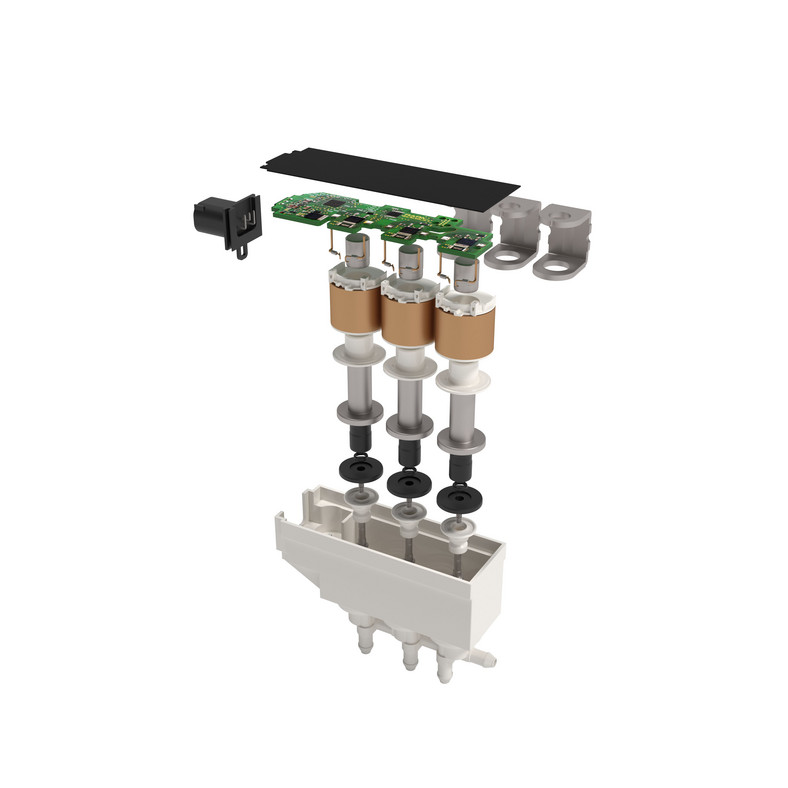

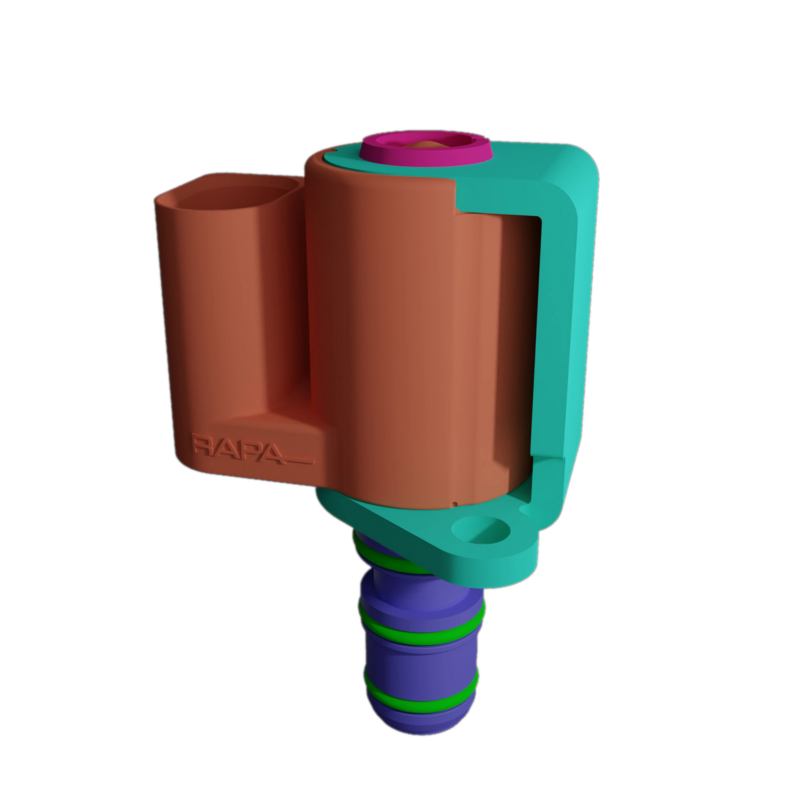

Our product and service portfolio includes customized valve solutions, fluid management systems, fluid control products and microfluidic components in accordance with the requirements of medical and analytical technology for mobile and stationary applications. Depending on the field of application, our valves, solenoid valves and fluid components help to create heat, cold, smooth production and safety. They block, relieve, distribute or mix gaseous and liquid media of various chemical compositions depending on pressure and temperature.

Our components - your requirements

Industrial technology

When special valves are used in industrial technology, the focus is on operational safety. In this area, valves come into partial or direct contact with media and liquids that are transported, processed or discharged in industrial processes - for example when handling gases in production systems or liquids in technical systems in a wide range of industries.

Process and analysis technology

Special valves used in process and analysis technology require a high level of chemical and mechanical resistance, as these valves are used in devices that are used in industrial, scientific or technical areas for monitoring, controlling or analyzing gases and liquids. They do not come into direct contact with end products or users, but are designed for the safe handling of aggressive or sensitive media.

Our components meet your expectations and fulfill your goals

- High precision and functionality

- Resistance to aggressive media and gases

- Use of internal materials

- Small internal volume

- Easily flushable design (easily flushable internal valve or system cavities)

- Low power consumption to reduce heat transfer to the medium

- Media separation

- Separation between the medium (liquid or gas) and the valve mechanism

- Energy efficiency

- Weight saving

- Reliability and operational reliability

- Long product life cycle

- Product availability

Request a quote & implementation for development projects

Special project?

Do you have a specific project inquiry or need a special solution or service? Then please send us a few brief details about your request.

We will be happy to help you at any time and put you in touch with the right expert for your request.