High-precision dosing of liquids or gases

Microfluidics, an innovative field of research, enables the precise handling of fluids in tiny channels and has many applications in biomedical and chemical analysis. One of the greatest challenges in microfluidics is the production of precise and reliable components, such as micropumps and valves. These must not only be able to precisely control extremely small volumes, but must also be resistant to chemical and physical stresses. In addition, the integration of different functional units into a single microfluidic system requires a high degree of accuracy and compatibility of materials. Miniaturization therefore places high demands on the precision of production and quality assurance.

Micro pump

High-precision dosing pump

Reliable and precise components are essential in industry in order to make production processes efficient and safe. Our stainless steel piezo micropump offers precisely these properties and enables manufacturers to develop innovative solutions for a wide range of industrial applications.

The micropump is based on advanced piezo technology and is characterized by outstanding features. With an operating life of 10,000 hours, it sets new standards in terms of reliability and durability. Compared to other pumps, our micropump offers up to twice as long a service life. It also boasts excellent back pressure characteristics and high bubble tolerance, which further improves its performance.

Key features

- Piezo technology

- Material: Stainless steel

- Extremely durable

- Excellent back pressure characteristics

- Large bubble tolerance

- Self-priming

- Low energy consumption

- Autoclavable

Tested series product

Customizing | Customizable

At RAPA Industry, we understand that industrial applications often require customized solutions. Another major advantage of our micropump is its flexibility and adaptability to specific requirements. Technological parameters such as dosing accuracy, back pressure stiffness, size, energy consumption, particle resistance, bubble tolerance and "free flow" protection can be flexibly adapted to individual requirements.

Additional control electronics

We offer suitable control electronics for operating the micropump.

Applications

Our piezo micropump is widely used in various industrial sectors, including machine and equipment construction, the automotive industry, the chemical industry, pharmaceuticals and in the manufacture of disinfection and cleaning equipment. It is ideal for precise dosing of liquids, analytical measurements and in systems that require accurate handling and supply of materials.

Fast and cost-effective series production

Thanks to its scalability and established procedures and processes, our micropump can be produced quickly and cost-effectively in different quantities. Both small and medium quantities of up to 10,000 units as well as large-scale projects can be realized. Our micropump is ideally suited for use as disposable units.

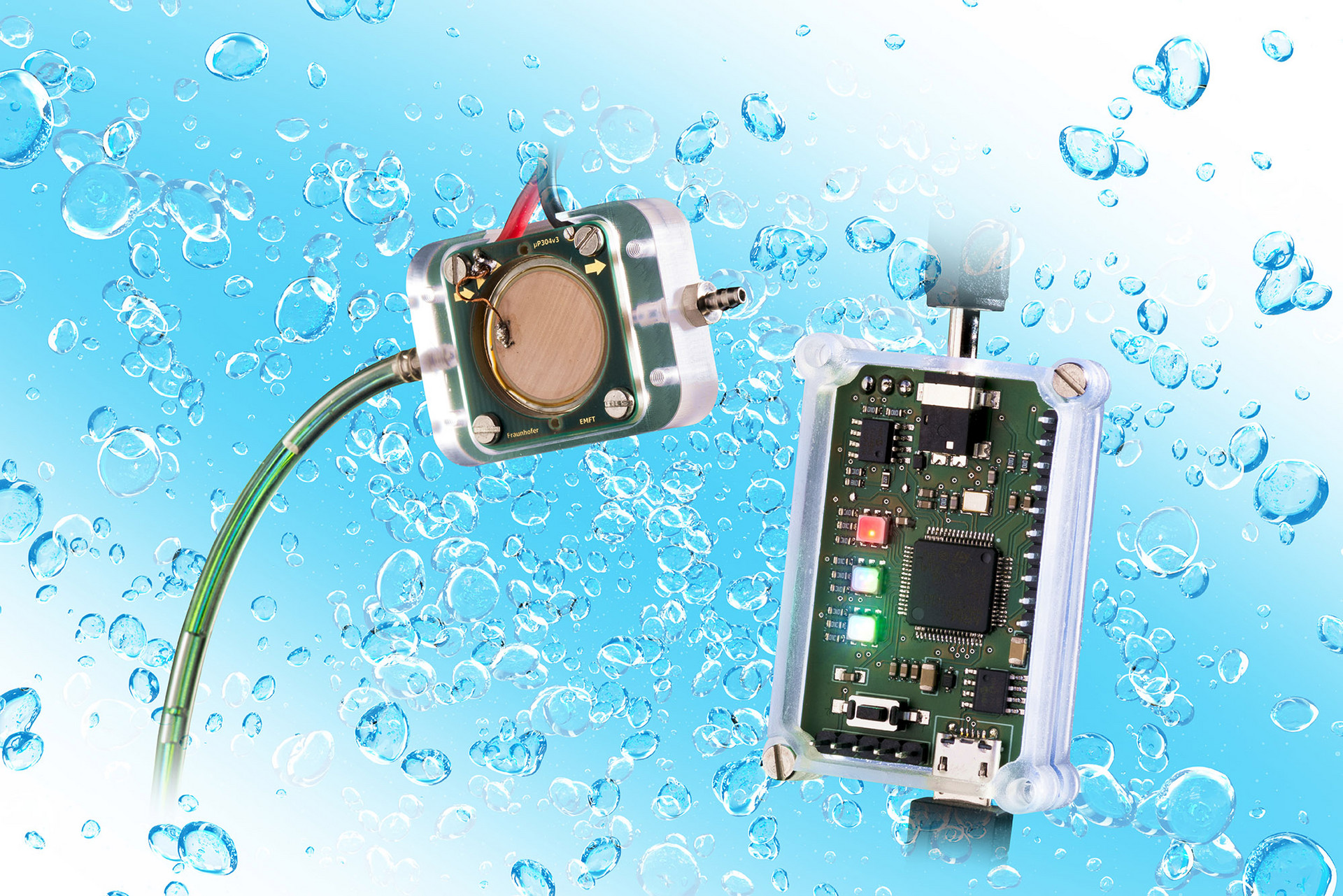

Evaluation kit micropump

Would you like to test the performance and functionality of our piezo micropump for your specific applications?

With our evaluation kit, we offer you the opportunity to test the pump extensively and gain your own application-specific experience. The evaluation kit contains everything you need to use the pump in your laboratory or development project.

Contents

- 2 micropumps

- ECU V5, PC-USB-I2C interface and accessories such as cables

- hoses, hose connectors and filters

Self-sensing technology

Micropump monitors itself and detects anomalies without additional external sensors

The integration of artificial intelligence (AI) enables our self-monitoring micropump to reliably detect gas bubbles and their size. By evaluating the micropump's control signal using AI and the piezo effect, the pump can react precisely and in good time to any gas bubbles that occur.